Services

Multi-Disciplined

Woodhawk is fully experienced in multiple automation-related fields and continues to grow to meet the needs of our customers.

Panel Shop

Woodhawk Controls is a premier control panel builder with thousands of UL listed panels installed throughout the USA and Canada. This is our core business and we continue to expand to multiple markets around the world.

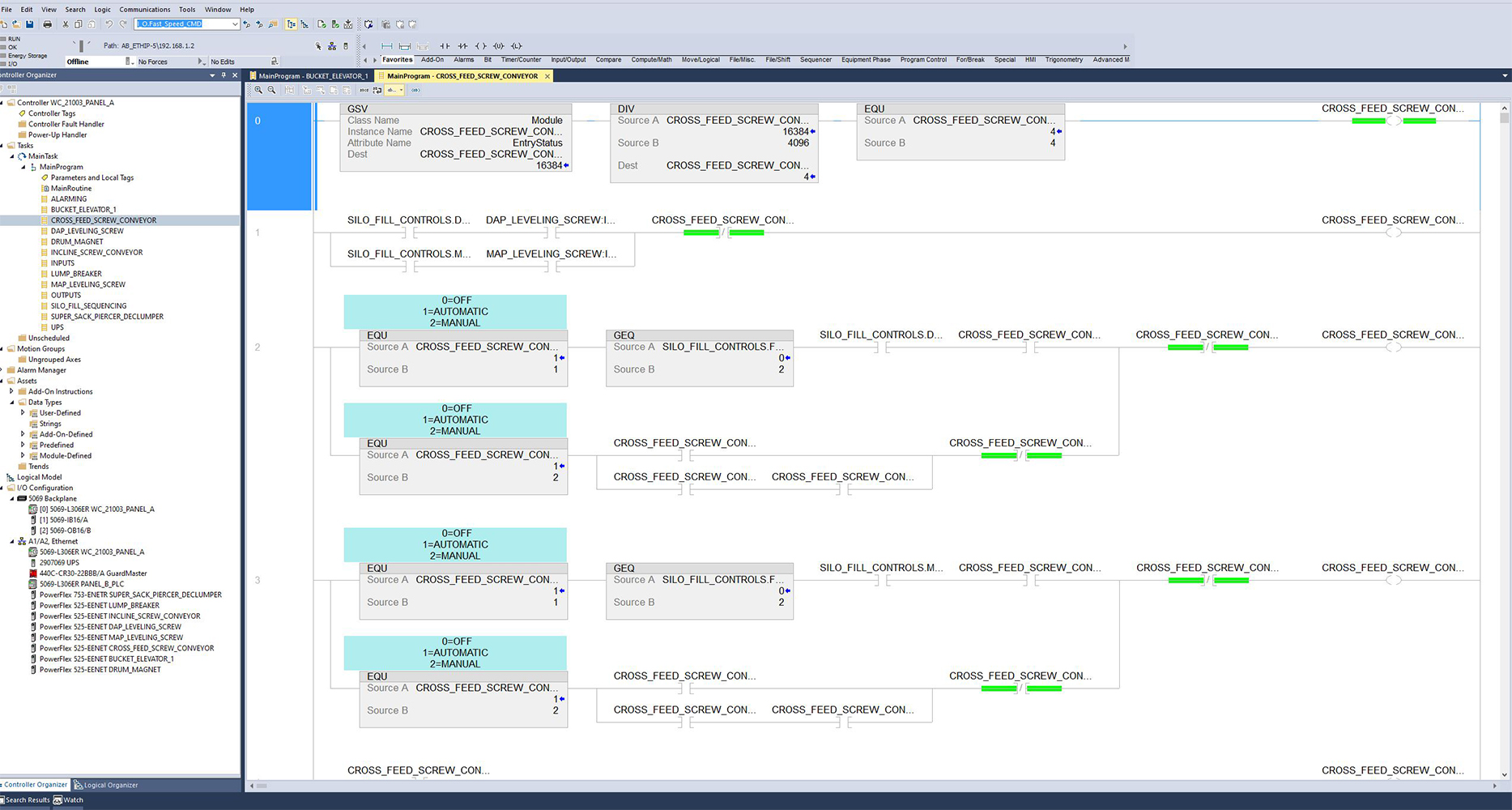

Automation

Woodhawk Controls has expanded to become a Controls System Integrator with full PLC/HMI/SCADA programming services. We are a Rockwell Allen-Bradley Bronze System Integrator with a focus on becoming the exclusive Silver Integrator in North Idaho. This part of our business is growing rapidly and we are committed to expanding our personnel to keep pace with our customer requests.

Fabrication

Woodhawk Controls has the in-house skill set to design and fabricate custom pump and water conditioning skids along with various automation equipment. We offer 3D modeling services as well as design assistance and expertise.

Rockwell Automation

System Integrator Partner

TOSIBOX Certified System Integrator

www.TOSIBOX.com

Schneider Electric Registered System Integrator

Ignition

Certified System Integrator

UL508A & UL698A

Control Panel Manufacturing Facility

Electrical and Control System Engineering;

Substation, Transformer, Switchgear, MCC Specifications and Design, Motor Control design, Lighting Engineering, and Design

National Electrical Code Interpretation

Complete Electrical Construction Packages

Instrumentation Engineering

P&ID Development, ISA Specifications/Datasheets, Instrumentation Sensing Technology Selection, Instrument Loop Diagrams DCS, PLC Hardware Specifications, and HMI/SCADA Hardware Specifications

Instrument and Electrical Construction Packages

Panel Design

Motor and Process Control Panel design, PLC and GUI Panels, Protective Relay Panels, Remote Alarm, Telemetry Panels, Power Distribution Panels, Utility Racks and Panels, Operator Consoles, Energy and Demand Metering/Controls

Modification of Existing Panels to Achieve UL Compliance

Mechanical/Electrical Design and Integration

System-Level to Component Level Design, SolidWorks 3D Modeling and Fabrication Drawings with Complete BOM’s Machinery and Integration

Build

From Fabrication and Assembly – To Full System Integration

Woodhawk Controls can build & fabricate any size project from the smallest push button box to large multi-door PLC enclosures, relay racks, or custom automated machinery. Woodhawk Controls' expertise covers all major equipment brands, including but not limited to: ABB, Allen-Bradley, Eaton, Square D/Schneider, and Siemens. Whether it's electrical, hydraulic, pneumatic, or mechanical, Woodhawk Controls has the knowledge and capability to build and program the most challenging of projects.

Fabrication

Panel & Console Fabrication & Assembly

Motor, Pump, Process Control Panels, PLC Panels, GUI Panels, Protective Relay Panels. Remote Alarm and Telemetry Panels, Power Distribution Panels, Operator Consoles, Energy and Demand Metering Controls, Automatic Power Factor Correction Systems, Utility Rack/Panels and Custom Enclosures (UL).

Metal Fabrication and Machining

Full-Service Machine & Weld Shop

MIG/TIG Welding of Aluminum, Steel, SS, Exotic Alloys,

Frames, Fixtures, Jigs & Prototypes

Mechanical/Electrical Integration and Assembly

Control Systems Integration

PLC Systems

DCS Systems

HMI Applications

SCADA Applications

Quality Control Systems (QCS)

Information Systems & Software Development

WAN/LAN Networking, Radio & Antenna Systems

Serial Communication

Cellular Communications

Historians

Logging & Reporting

Network security assessments and consulting

Managed switch deployments

On staff Cisco Certified Network Engineer

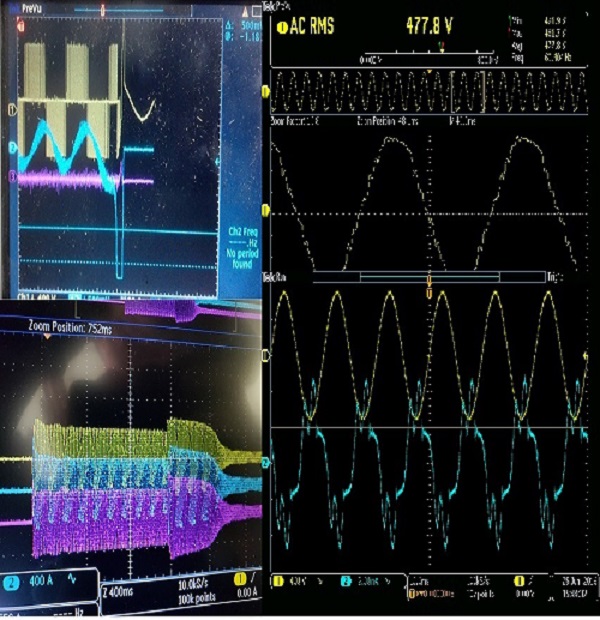

Testing and Studies

Woodhawk Controls can safely perform your system studies including Production Data collection, optimization studies, Root Cause analysis for downtime and production out of range incidents, Network Security/Vulnerability assessment, Power Quality Studies, Backup Power runtime analysis, NFPA 70E Arc Flash Assessments, Thermography and IR scans, Equipment vibrations analysis, Electrical and equipment accident investigations.

Testing

Instrumentation and Current loop calibration and testing. I/O checkouts, VFD (Variable Frequency Drive), vibration analsys, power quality and harmonic measurements, capacitor reforming, transformer testing, and thermal imaging.

Power System Studies

Load flow analysis, short circuit coordination, arc flash analysis, and hazardous area labeling. Power quality measurement & verification, as well as harmonic analysis and mitigation.

Energy Conservation Studies

Energy audits, payback and ROI analysis, and assistance with incentive programs.

Training and Customer Service

Training

Woodhawk Controls offers top quality training on all of our hardware and software products whether at our location or yours. This can either be product/project-specific or it can be generalized training, as basic or advanced as required.

Customer Service

A long-term customer relationship is our goal and Woodhawk Controls is dedicated to providing exceptional service and support. To that end, Service Contracts from basic assistance to on-call 24/7/365 are available.